|

CCD

- Catalytic Combustion Detector

|

39

|

|

|

|

About as sensitive as a TCD, the Catalytic Combustion Detector has the hydrocarbon selectivity of an FID, plus the ability to operate on air alone. Because the CCD requires no compressed gases like hydrogen or helium, it can be used in SRI's Gas-less GCs where our built-in, "whisper quiet" air compressor supplies the ambient air carrier gas. The CCD detector can also be used as a hydrocarbon monitor in non-chromatographic applications where the CCD senses the total hydrocarbon content of a flowing air stream, or as a hydrogen/hydrocarbon leak detector.

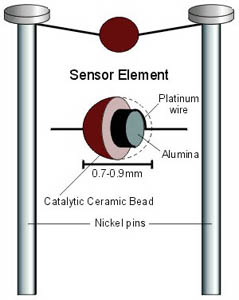

The CCD sensor, shown above, is rugged and can be expected to last a long time. A second sensor is included in the detector housing at no extra cost, providing a built-in replacement should the first sensor become inoperable. Replacement sensor sets install in minutes without tools and are very economical, making this detector a good choice for academic settings where the sensors may be damaged by inexperienced operators.

Our CCD detector consists of a tiny coil of platinum wire embedded in a catalytic ceramic bead. A small electric current flows through the patinum coil, heating the ceramic bead to around 500oC. The CCD is maintained in an oxidative environment by using air carrier gas. When a hydrogen or hydrocarbon molecule impacts the hot bead, it combusts on the surface and raises the temperature and resistance of the platinum wire. This resistance change causes the detector output signal to change, thus producing a peak. The brass detector housing is mounted on a stainless steel bulkhead fitting, which is mounted directly in the wall of the GC column oven.

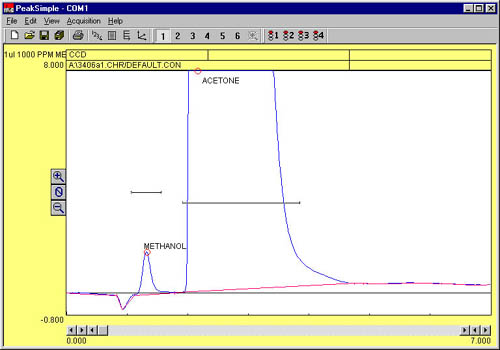

| This chromatogram shows a separation of 1000ppm methanol from acetone at 150oC and air carrier from the Gas-less GC's built-in air compressor. The negative peak at the beginning of the run is water. |  |

|

8690-2007

|

CCD detector

|

£1,088.00

|

|||

|

8670-2007

|

Replacement CCD detector housing (2 sensors in 1 housing) |

£96.00

|

|||