|

10

Port Gas Sampling Valves & 22 Port Stream Selector Valves

|

65-66

|

- Heated, thermostatted

valve oven

- Standard &

custom plumbing configurations

- Electronically

actuated with PeakSimple control or manually actuated

- 1or 2 valve capability

SRI uses 10 port gas sampling valves because they provide more analytical flexibility for the same cost as four or six port valves. 10 port gas sampling valves can easily be plumbed to replicate the function of the simpler valves, while offering many other possible configurations, including: Inject Only, Inject and Backflush, Pre-column Backflush to Vent, Column Sequence Reversal, Alternate Loop Inject, and Dual Loop-Dual Column. Many more plumbing configurations are possible, especially when multiple valves are plumbed together.

The heated valve oven can be adjusted from ambient to 175°C (up to 300°C for a manual valve). It mounts on the 8610 GC, and can accommodate two electrically actuated and one manually operated valve. Because the valve oven is right next to the column oven, tubing runs are short with no cold spots, which results in sharper peaks.

|

|

|

Shown above are dual 10-port gas sampling valves in the heated valve oven of a dual TO-14 Air Concentrator. |

Shown above is a 22-port stream selector valve on our 10 position Purge & Trap Autosampler. |

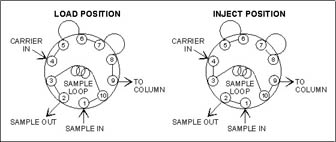

| The valve plumbing configuration shown at right is the standard 6-port configuration. The sample loop is inserted into the carrier gas stream when the valve is rotated to the INJECT position. |  |

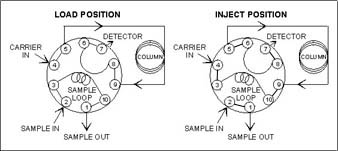

| The same 10-port valve can also be configured to backflush the column when the valve is rotated. Backflushing can often shorten the analysis by eliminating the need to program the column temperature up to elute high boiling analytes. |  |

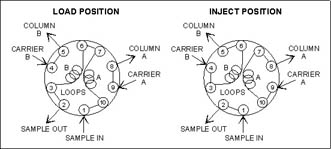

| A single 10-port valve can be plumbed to inject the same sample onto two separate loops. This is especially useful when two different carrier gas types are used, or when the detectors employed have very different sensitivities and need different sample sizes injected. |  |

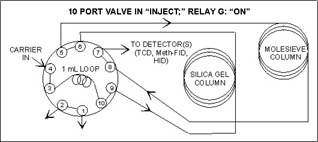

| The 10-port valve configuration shown at right is our Multiple Gas Analyzer #1 (MG#1) valve. In the LOAD position, the sample loop is filled with fresh sample gas, and the Silica Gel column is downstream of the MoleSieve column. When the valve is rotated into the INJECT position (shown), the contents of the loop are flushed into the Silica Gel column, which is now upstream. The lightest analytes blow through onto the MoleSieve column for separation. The valve is then rotated back to the LOAD position, just prior to the elution of ethane, for the separation of C2-C6. |  |

|

8690-0063

|

10-port Manually actuated valve, plumbed & tested |

£1,088.00

|

|

8690-0065

|

10-port Electrically actuated valve, plumbed & tested |

£1,824.00

|

|

8690-0077

|

Automated 22-port, 10-stream selection valve, stand-alone, plumbed & tested |

£4,088.00

|

| 8690-0088 | Thermostatted valve oven, mounted on an 8610C GC |

£728.00

|

|

8690-0091

|

Narrow heated, thermostatted valve oven mounted on an 8610D GC |

£728.00

|

| 10 Port Gas Sampling Valves & 22 Port Stream Selector Valves |

65-66

|