|

Method

5030 & 5030/5035 Compliant Purge & Trap

|

76-77

|

|

|

|

Method

5030 Compliant

Purge & Trap |

Built into the Model 8610C GC, the SRI Purge & Trap concentrates the volatile organic compounds (VOCs) in a gas, water, or soil sample onto two adsorbent traps, from which they are automatically desorbed onto the GC column. The Method 5030/5035 Compliant Purge & Trap is equipped with interchangeable purge heads. The 5035 purge head is a thermostatted (typically 40oC) sleeve which accepts standard 40mL VOA vials. The entire sleeve is mechanically agitated while purging to comply with the requirements of EPA Method 5035. The 5030 purge head uses low-cost, disposable 16mm test tubes which are purged at ambient temperature. For higher level soil samples or soil/methanol extractions, the test tube is more convenient and less expensive than VOA vials.

Operation of the Purge & Trap is completely automated by the PeakSimple data system that is built into the GC. Run parameters such as purge time, desorb heat, bake-out, vial temperature, and mechanical agitation are adjusted in a PeakSimple Event table.

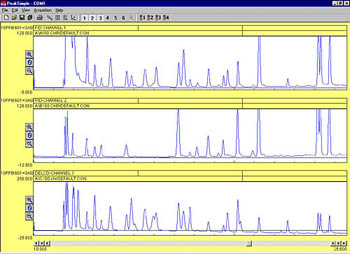

The SRI Purge & Trap is unique because it is equipped with two traps rather than one, and each trap can be heated independently at the adsorption temperature (typically 35-70oC), the desorption temperature (200oC), and the bake-out temperature (250oC). For most VOC applications, the first trap is Tenax-GR, and the second trap is Carbon Molecular Sieve. By setting the adsorption temperature of the Carbon MoleSieve to 50-60oC and the Tenax-GR to 35oC, water retention is dramatically reduced. By staggering desorption times, early eluting peaks from the hot Carbon MoleSieve trap are refocused on the temporarily cold Tenax-GR trap, resulting in much sharper peaks than otherwise possible (see the chromatograms on the following page).

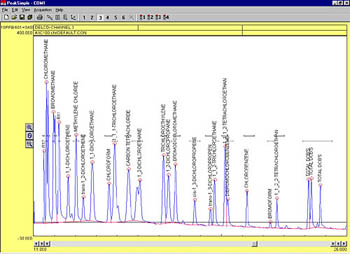

| By comparing the relative response, the three detectors make peak identification and confirmation easy. The FID responds to all hydrocarbons, the PID responds to some hydrocarbons and all aromatics, and the DELCD responds to halogens only. |  |

| The DELCD chromatogram is shown below in more detail. The DELCD is completely selective for compounds containing chlorine and/or bromine. Other analytes do not respond at all, even at very high levels. The DELCD actually operates on the FID's exhaust gases; therefore, all contaminants are pre-combusted by the FID to CO2 and H2O. | |

|

|

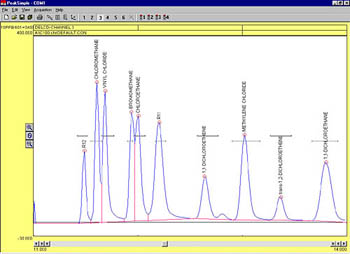

| The first few peaks in the 8021 standard, including vinyl chloride, are of special interest to many analysts. The chromatogram on the right shows the expanded detail of the first few peaks in the analysis (the VOC gases). Note the exceptionally good resolution and peak shape delivered by the SRI system with its dual trap technology. | |

|

8690-0052

|

Method 5030/5035 Compliant Purge & Trap with interchangeable purge heads |

£7,272.00

|

|

8690-0051

|

Method 5030 Compliant Purge & Trap |

£5,904.00

|

| Method 5030 & 5030/5035 Compliant Purge & Trap |

76-77

|