10-11

|

|

| By analyzing the gases dissolved in transformer oil, potential transformer faults can be avoided. ASTM D3612 provides for identification and quantification of dissolved gases intransformer oil by GC. The SRI TOGA GC uses the version referred to as D3612B, the direct injection technique where the dissolved gas extraction takes place inside the GC. This means that other than collecting the transformer oil in a glass airtight syringe, no sample preparation is necessary prior to injection into the TOGA GC. This helps to avoid contamination made possible by transferring the sample between various containers. |

The presence and quantities of certain gases in the transformer oil indicate four broad types of possible general fault conditions: |

|

|

|

Concentration

by Weight: Hydrogen 10.7ppb Oxygen 25.74ppm Nitrogen 76.65ppm Methane 70.6ppb Carbon monoxide 207.4ppb Carbon dioxide 518ppb Ethylene 120.9ppb Ethane 120.7ppb Acetylene 86.7ppb |

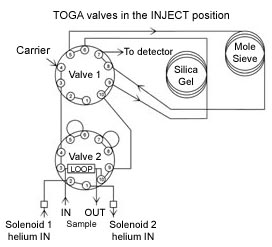

| While the transformer oil is being pumped through the gas extraction loop, the 10-port electrically actuated valves are in the LOAD position. During this time, the dissolved gases in the transformer oil permeate through the membrane, into the extraction chamber. When the valves are switched to the INJECT position, the contents of the loop are swept into the Silica Gel and Molecular Sieve 13X columns. |  |

|

By reconnecting a few tubing lines, the TOGA GC can be used to create dissolved gas standards. A Tedlar bag (or other container) filled with gas standard is connected to the standard pump. The standards preparation vessel is filled with sample liquid. The standard pump bubbles gas standard through the standards preparation vessel, equilibrating the liquid over time to a known concentration. |

|

8610-0031

|

TOGA GC System with HID detector and 1 channel data system |

DISCONTINUED

|

|||

|

8610-0032

|

TOGA GC System with TCD & HID detectors and 4 channel data system |

DISCONTINUED

|

|||

|

(VOLTAGE:

for 110VAC, use "part number-1" [ex: 8610-0032-1] for

220VAC, use "part number-2")

|

|||||

10-11