|

Heated

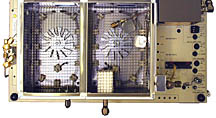

Flash Vaporization Injector

|

61

|

|

|

|

Thisparticular

8610C GC model has a standard on-column injector on the first oven,

and a heated flash vaporization injector upgrade on the second oven

(requires purchase of second on-column injector, also).

|

|

The heated flash vaporization injector is useful for applications which require flash vaporization of the sample prior to the column, such as desorption of SPME fibers or injection of extremely dirty samples where the nonvolatile residue must be trapped in the injection liner.

The injector's heater block can be thermostatted up to 300°C, and includes as standard equipment two injector liners: an inert Silcosleeve liner, and an unbreakable stainless steel liner, which allows for on-column mode.

The heated flash vaporization injector option is an upgrade to an existing On-column injector. Two heated injectors may be installed on the Model 8610C GC, but only one on the smaller Model 310. Where no need for a heated injector exists, we recommend using the standard on-column injector.

| 8690-0025 | Heated Flash Vaporization injector upgrade |

£728.00

|

| 8670-1034 | SilcoSleeve Liner (modified) for heated injector |

£24.00

|

| 8670-0072 | Narrow bore SPME injector sleeve |

£144.00

|

| Heated injection vs. on-column Injection: Pros and Cons |

| In the early days of GC, the column oven insulation was typically several inches thick. It was not then possible to insert a syringe through the oven wall to deposit the sample on the column and be assured that the sample would completely vaporize unless the injector was heated. On today's SRI Instruments GC, the oven wall is much thinner. This allows the syringe needle to penetrate well inside the column oven, thus depositing the sample into the bore of the column itself. As the temperature is programmed up, the sample is completely vaporized. Even high boiling analytes such as C44 hydrocarbons chromatograph well using on-column injection, since the area of the column where the sample is deposited follows the column oven temperature, and ultimately heats to a point where the C44 begins to migrate down the column. There is no need to employ a heated injector unless the sample needs to be split, or if the sample needs to be desorbed from a SPME fiber. In fact, the heated injector has some distinct disadvantages. The internal surfaces of the injector liner are more chemically active than the very inert interior of the column, so undesired adsorption and tailing can result when the sample is violently expanded in the hot interior of the heated injector. Also, the heated injector transmits some heat into the column oven because of its close proximity, making it harder for the oven to cool down close to ambient temperature. |