|

PTV

- Programmable Temperature Vaporization Injector

|

63

|

|

|

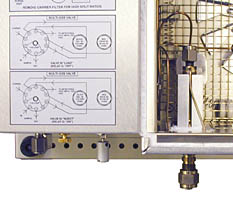

The Programmable Temperature Vaporization (PTV) option adds ballistic heating capability to the Heated Split/Splitless injector in order to accommodate large volume injections and thermal desorption applications. In the PTV mode, the insulation is removed from the Split/Splitless injector so that the column oven fan can cool the injector down between analyses.

A small amount of adsorbent material, like Tenax, is packed inside the PTV injector sleeve. The initial column oven temperature, which maintains the injector cool-down temperature, should be set slightly higher than the boiling point of the solvent. As a large volume of sample is injected, the solvent vaporizes and passes through the adsorbent material and out the split vent. The split vent and carrier gas are under PeakSimple control. The carrier gas can be turned OFF during the PTV ballistic heating, in order to preheat the adsorbed analytes prior to desorbing onto the column.

|

|

|

8690-7034

|

PTV

& Split/splitless injector upgrade

|

£1,824.00

|

|

8690-8034

|

PTV

& Split/splitless injector with 10-port valve

|

£3,640.00

|

| PTV - Programmable Temperature Vaporization Injector |

63

|